Automotive recalls are no longer isolated quality events. Today, poor automotive recall management can spiral into multi-crore financial losses, operational disruption, and long-term brand damage.

What begins as a defect in a small batch of components often expands into a recall affecting thousands, or even millions, of vehicles. The reason is rarely the defect alone. In most cases, recalls escalate because manufacturers lack precise visibility into which exact parts went where, and which vehicles are actually at risk.

Why Automotive Recalls Escalate Into Multi-Crore Problems

Most recalls don’t become expensive overnight. They become expensive because of uncertainty.

When OEMs and Tier-1 suppliers cannot confidently identify:

- Which exact parts are defective

- Which vehicles contain those parts

- Where those vehicles are in the supply chain or the aftermarket

They are forced to over-recall.

Over-recalling Is a Risk-Management Reaction

In the absence of verified data, companies default to caution:

- Recalling entire production batches

- Expanding recall windows across months

- Including unaffected dealers, regions, or vehicle variants

While this approach reduces legal risk, it massively increases recall cost control challenges.

According to industry estimates:

- Limited traceability can increase recall handling costs by 30–60%

- OEMs globally spend billions annually due to overly broad recalls

- Warranty claims and service congestion multiply when the recall scope is unclear

This is not a quality failure. It is a traceability failure.

The Hidden Role of Traceability in Automotive Recall Management

At its core, effective automotive recall management depends on one capability:

The ability to trace a specific part across its entire lifecycle, with certainty.

Without this, recall decisions are based on assumptions rather than facts.

What Happens When Traceability Is Weak?

- Parts cannot be uniquely identified beyond batch or lot numbers

- Supplier data is disconnected from vehicle production data

- Aftermarket movement is invisible

- Verification at dealerships is manual and error-prone

As a result:

- Recall scope expands unnecessarily

- Response time increases

- Customer trust erodes

This is where traceability in automotive manufacturing becomes mission-critical, not just for compliance, but for financial survival.

Batch-Level vs Part-Level Recall: The Cost Difference Is Massive

One of the biggest contributors to recall inflation is reliance on batch-level traceability.

Batch-Level Recall (Traditional Approach)

- Tracks components by lot or production batch

- Cannot distinguish between individual units

- Forces OEMs to recall all vehicles linked to that batch

Impact:

- Large recall populations

- Higher logistics and service costs

Increased warranty exposure - Brand damage due to scale

Part-Level Recall (Modern, Data-Driven Approach)

- Each part has a unique, verifiable digital identity

- Exact parts can be traced to:

- Specific vehicles

Specific dealers - Specific customers

- Specific vehicles

Impact:

- Precise recall scope reduction

- Faster recall execution

- Lower operational disruption

- Stronger regulatory confidence

Part-level traceability transforms recalls from blanket actions into surgical interventions.

How Faster Recall Containment Reduces Cost and Brand Damage

Time is the most underestimated factor in recall cost.

The longer it takes to:

- Identify affected vehicles

- Notify the right stakeholders

- Verify parts at the point of service

…the more expensive the recall becomes.

Faster Containment Delivers Measurable Benefits

- Lower logistics and replacement costs

- Reduced service network overload

- Fewer secondary warranty claims

- Improved customer communication and trust

In contrast, delayed containment:

- Amplifies negative media coverage

- Invites regulatory scrutiny

- Creates long-term brand perception issues

This is why recall cost control is directly tied to data speed and accuracy, not just defect severity.

Why Part Verification Is Critical During Recalls

Even after a recall is announced, another challenge remains: verification.

Without reliable part verification:

- Dealerships rely on visual checks or manual records

- Counterfeit or grey-market parts may enter the recall flow

- Incorrect replacements can occur

A recall is only effective if:

- The right vehicle is serviced

- The right part is replaced

- The action is digitally verified and recorded

This closes the recall loop and protects OEMs from repeat exposure.

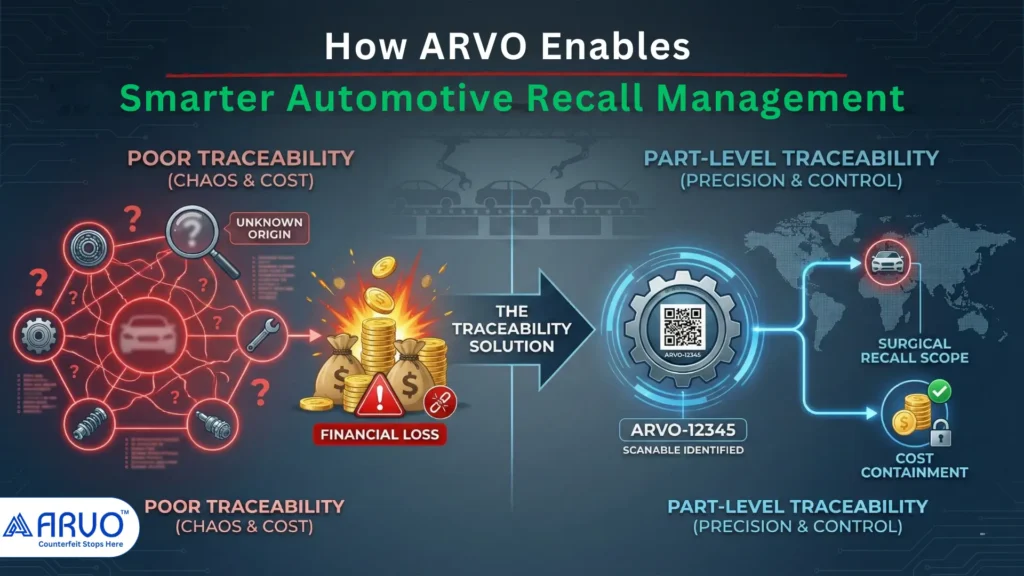

How ARVO Enables Smarter Automotive Recall Management

ARVO helps automotive manufacturers shift from reactive recalls to controlled, data-driven recall management.

How ARVO Supports Recall Scope Reduction

- Enables part-level traceability using secure, non-clonable identifiers

- Links part identity to production, logistics, supply chain, and aftermarket movement

- Allows OEMs to identify exact exposure, not assumptions

How ARVO Improves Recall Cost Control

- Faster identification of affected vehicles

- Reduced recall population size

- Lower logistics, service, and warranty costs

How ARVO Strengthens Recall Execution

- Real-time part verification at dealerships

- Digital audit trails for regulators

- Improved coordination across OEMs, suppliers, and service networks

Instead of expanding recall scope to stay safe, ARVO allows teams to stay precise and confident.

The Bottom Line: Better Traceability Contains Recalls Before They Explode

Automotive recalls will never disappear. But multi-crore recall losses are not inevitable.

They are often the result of:

- Limited traceability

- Slow data access

- Inability to verify parts confidently

OEMs that invest in modern automotive recall management systems, built on part-level traceability, gain:

- Smaller recall scopes

- Faster containment

- Lower financial and reputational risk

In today’s regulatory and customer-driven environment, traceability is no longer optional. It is strategic.

Ready to Contain Recalls Before They Escalate?

If recall control, cost reduction, and visibility across your automotive supply chain are priorities, the right traceability foundation makes all the difference.

ARVO helps OEMs and suppliers implement part-level traceability, verify components across the lifecycle, and manage recalls with confidence.

Book a call with ARVO to see how smarter traceability can transform your recall strategy

Validate recall ROI before scaling

Reduce exposure without disrupting operations

Schedule a conversation today and take control of recall risk, before it becomes a multi-crore problem.

Frequently Asked Questions (FAQs)

1. What is automotive recall management?

Automotive recall management is the process of identifying, containing, and resolving vehicle defects after production. It includes detecting affected parts, determining recall scope, notifying stakeholders, verifying components, and ensuring corrective actions are completed. Effective automotive recall management relies on accurate traceability data to prevent unnecessary recall expansion and control costs.

2. Why do automotive recalls often expand beyond the affected batch?

Recalls expand when manufacturers lack precise traceability. Without part-level visibility, OEMs cannot confidently isolate defective components, forcing them to recall entire batches or extend production periods as a risk-mitigation measure. This over-recalling significantly increases recall costs, operational disruption, and brand impact.

3. What is the difference between batch-level and part-level recall traceability?

Batch-level traceability tracks groups of parts produced together, while part-level traceability assigns a unique identity to each individual component. Batch-level recalls result in broader recall scope, whereas part-level traceability enables targeted recalls, faster containment, improved recall scope reduction, and better recall cost control.

4. How does traceability help reduce automotive recall costs?

Traceability in automotive manufacturing allows OEMs to quickly identify exactly which vehicles and parts are affected. This reduces recall population size, speeds up containment, lowers logistics and warranty expenses, and minimizes reputational damage. Faster and more precise recalls directly translate into measurable cost savings.

5. How can ARVO help improve automotive recall management?

ARVO helps manufacturers implement part-level traceability and real-time part verification across the supply chain. By providing accurate exposure analysis and secure component identification, ARVO enables OEMs to reduce recall scope, control recall costs, and execute recalls with greater confidence and regulatory readiness.