The electric vehicle industry is entering a compliance-driven phase. What began as a race toward electrification is now evolving into a race toward traceability, sustainability, and regulatory transparency. At the center of this shift is the concept of a digital battery identity, often referred to as a Battery Passport. In India, this can be understood as a “Battery Pack Aadhaar”: a unique digital identity assigned to every battery pack that enables complete lifecycle traceability.

This is no longer a strategic option. It is rapidly becoming a regulatory expectation.

Manufacturers that fail to implement structured digital traceability systems risk export barriers, audit delays, and escalating compliance costs. Those who act early gain operational visibility, regulatory readiness, and long-term competitive advantage.

The Global Regulatory Push Toward Battery Traceability

Battery traceability is not a theoretical concept. It is being formalized into law.

In the European Union, the battery regulation adopted under the framework of the European Commission requires a digital battery passport for industrial and EV battery traceability above specific capacity thresholds. This passport must include:

- Carbon footprint declarations

- Recycled content percentages

- Material composition details

- Due diligence documentation

- End-of-life handling information

The objective is clear: ensure transparency across the entire battery lifecycle, from raw material extraction to recycling.

For manufacturers exporting to Europe, compliance is not optional. Without structured digital documentation, market access becomes difficult or impossible.

India is moving in a similar direction. Under the Battery Waste Management Rules, producers are responsible for Extended Producer Responsibility (EPR), mandating traceability of batteries placed in the market and their end-of-life collection. As India strengthens EV safety standards and recycling accountability, digital traceability will become foundational.

The regulatory direction is consistent across geographies:

- Lifecycle transparency

- Environmental accountability

- Digital documentation readiness

- Audit accessibility

Battery manufacturers must prepare accordingly.

Why Manual Tracking Systems Are No Longer Sufficient

Despite regulatory momentum, a significant portion of Indian EV battery manufacturers still rely on:

- Spreadsheet-based tracking

- Paper batch records

- Fragmented ERP entries

- Manual audit compilation

While these systems may function operationally, they create structural weaknesses in compliance readiness.

Manual processes result in:

- Delayed data retrieval during audits

- Inconsistent documentation formats

- Increased risk of human error

- Difficulty in linking cell-level data to pack-level identity

- Limited end-to-end lifecycle visibility

When regulators or OEM partners request batch-level or pack-level traceability, teams often require days or weeks to compile data. In an environment where compliance audits are tightening, this delay becomes a business risk.

Digital traceability is not about replacing ERP systems. It is about creating a structured identity layer that connects manufacturing, compliance, and lifecycle events into a unified record.

The Business Risks of Non-Compliance

The cost of ignoring digital battery identity frameworks extends beyond regulatory penalties. It affects commercial viability.

Key risk areas include:

- Export rejection due to non-compliance with international battery passport standards

- Delays in product approvals or certifications

- Increased insurance scrutiny following safety incidents

- Warranty disputes without a verifiable batch history

- ESG reporting inconsistencies affecting investor confidence

- EPR non-compliance penalties under Indian regulations

In global supply chains, traceability is increasingly becoming a prerequisite for OEM partnerships. Tier-1 suppliers are expected to provide structured battery data, not just production outputs.

A manufacturer without digital battery identity systems risks being excluded from future-ready supply chains.

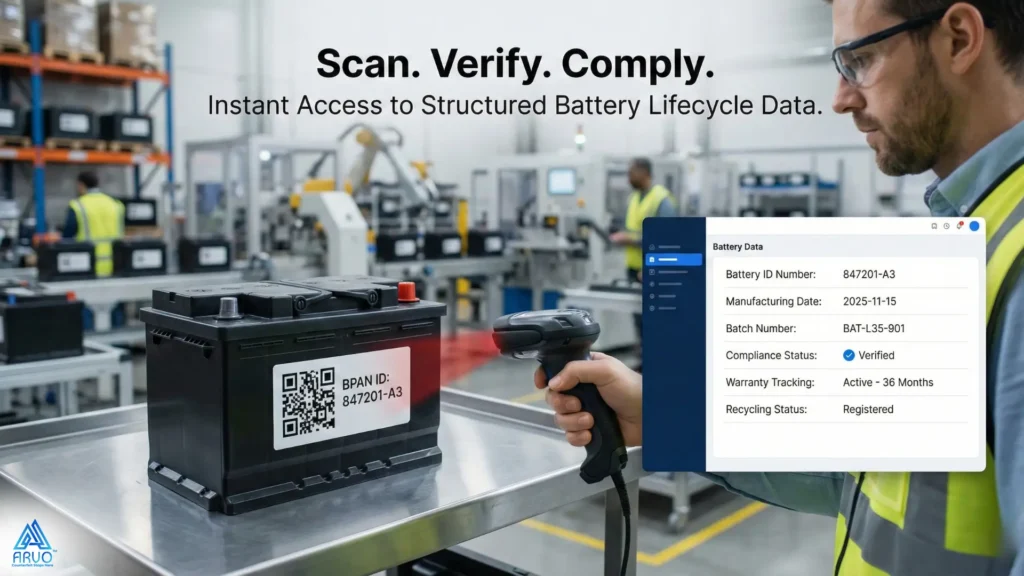

The Role of a Battery Pack Aadhaar System

A Battery Pack Aadhaar system assigns a unique digital identifier to each battery pack at the time of manufacturing. This identifier remains attached to the battery throughout its lifecycle.

The system enables:

- Unique pack-level identification

- Digital storage of compliance and testing data

- QR-based instant retrieval

- Lifecycle event logging

- End-of-life traceability

Such a system ensures that at any stage, production, vehicle integration, service, or recycling, authorized stakeholders can access verified data.

A structured digital identity layer bridges the gap between regulatory compliance and operational efficiency.

Industry Data Points That Demand Attention

The global EV battery market is expanding rapidly. According to international energy assessments, EV battery demand is projected to multiply several times by 2030. With growth comes regulatory scrutiny.

Consider the following realities shaping the industry:

- Europe’s battery regulation enforces mandatory carbon footprint declarations for EV batteries entering its market.

- Sustainability-linked financing increasingly requires verified lifecycle reporting.

- Recycling mandates are strengthening, requiring documented material recovery.

- OEM procurement processes now include ESG and traceability assessments.

In this context, digital traceability is not a future trend. It is a current procurement and compliance requirement.

Manufacturers that digitize early will be structurally prepared. Those who delay will face compressed implementation timelines under regulatory pressure.

How BPAN Framework Supports Compliance Without Disruption

ARVO’s Battery Pack Aadhaar Number (BPAN) framework is designed to align with evolving regulatory requirements while integrating smoothly with existing operational systems.

The BPAN approach focuses on:

- Assigning a unique digital identity to every battery pack

- Generating QR-based verification mechanisms

- Structuring compliance data in audit-ready formats

- Linking lifecycle events in a centralized system

- Enabling scalability for export markets

Importantly, the framework does not require a complete operational overhaul. It works alongside current manufacturing processes and ERP environments.

By creating a digital identity layer rather than replacing internal systems, manufacturers can transition toward compliance without production disruption.

The Strategic Advantage of Early Adoption

Companies that implement battery passport frameworks early gain measurable benefits:

- Reduced audit preparation time

- Faster regulatory approvals

- Stronger OEM and investor trust

- Improved lifecycle analytics

- Better risk mitigation

Early adoption also enables proactive ESG positioning. As sustainability reporting becomes standard practice, having structured lifecycle data improves credibility with global partners.

Digital traceability should be viewed as infrastructure, not as an optional add-on feature.

Preparing for the Inevitable Transition

The transition toward digital battery identity systems is accelerating. Manufacturers should assess their readiness across:

- Pack-level unique identification

- Digital documentation accessibility

- Carbon and material reporting capability

- EPR traceability processes

- Export compliance alignment

A readiness assessment allows organizations to identify gaps before regulations tighten further.

The cost of implementation is manageable when planned strategically. The cost of reactive compliance under deadline pressure is significantly higher.

Conclusion: Compliance Is Becoming Competitive Advantage

The concept of a Battery Pack Aadhaar represents more than regulatory alignment. It represents operational modernization.

As EV markets mature, transparency and accountability will define industry leaders. Manufacturers that embrace digital battery identity frameworks today will be positioned for:

- Global market access

- Stronger compliance posture

- Operational efficiency

- Long-term sustainability alignment

The shift is not speculative. It is regulatory, structural, and accelerating.

How ARVO Can Help

At ARVO, we help EV manufacturers implement the BPAN framework, a structured, compliant, and scalable Battery Pack Aadhaar system aligned with global regulations.

We don’t disrupt your operations.

We enable compliance without chaos.

🔗 Read more about BPAN and download the BPAN Readiness Checklist today.

Let ARVO help you future-proof your battery compliance strategy.

👉 Contact us: https://onearvoventures.com/contact-us/

Frequently Asked Questions (FAQs)

1. What is a Battery Passport in EV manufacturing?

A Battery Passport is a digital record that stores lifecycle data of an EV battery, including sourcing, manufacturing, usage, and recycling information. It ensures compliance, safety, and transparency.

2. Is Battery Passport mandatory in India?

While India is progressively tightening battery compliance under waste management and safety regulations, global export markets like the EU already mandate digital traceability. Indian manufacturers exporting to such markets must comply.

3. How does BPAN differ from traditional ERP tracking?

Traditional ERP systems store production data but often lack lifecycle linking and compliance-ready reporting. BPAN creates a structured digital identity per battery pack with full traceability and audit readiness.

4. What happens if a manufacturer does not implement battery traceability?

Non-compliance can result in export rejection, regulatory delays, audit failures, penalties, and loss of OEM trust.

5. How quickly can BPAN be implemented?

Implementation timelines depend on operational scale, but ARVO’s framework is designed for seamless integration without disrupting existing production systems.