The Growing Challenge in Automotive Supply Chains

Today’s automotive OEMs are grappling with unprecedented complexity in their global supply networks. With the average vehicle containing around 30,000 components sourced from thousands of suppliers across different continents, achieving clear visibility and traceability using traditional methods is no longer sustainable.

This complexity brings a host of vulnerabilities:

- Counterfeit parts are infiltrating supply chains, costing the industry over $45 billion annually

- Limited traceability during quality issues or recalls

- Regulatory compliance hurdles across regions

- Inefficiencies in inventory management, leading to production delays

- Elevated safety and liability risks

Without strong supply chain transparency, manufacturers face growing difficulty in maintaining quality control, protecting their brand, and meeting consumer and regulatory expectations.

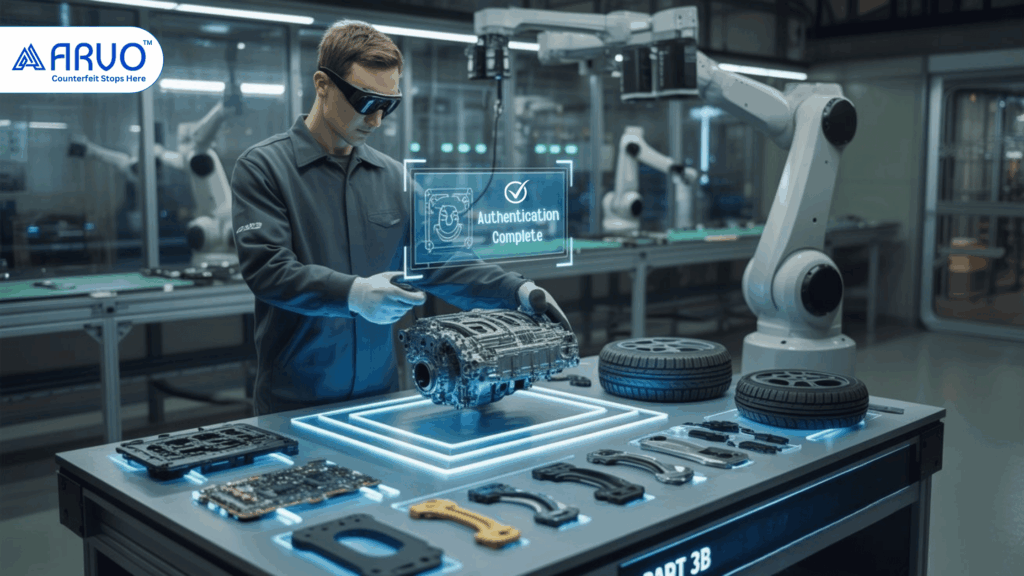

Smart Labels: Transforming Automotive Manufacturing

Smart labeling technologies are emerging as a powerful solution for modern automotive supply chains. Unlike traditional barcodes, smart labels offer dynamic, multi-layered security and tracking capabilities that enable real-time monitoring and authentication across the supply chain.

Advanced smart labeling systems include:

- Copy-proof codes that are nearly impossible to replicate

- Invisible watermarking for discreet verification

- Tamper-evident seals to flag unauthorized access

- Blockchain integration for immutable, end-to-end traceability

By implementing smart labels, OEMs can gain operational efficiencies, reduce losses from counterfeits, and improve overall supply chain agility, all with seamless integration into existing ERP and manufacturing systems.

Track and Trace: From Raw Materials to Finished Vehicles

Modern track and trace solutions allow OEMs to follow each component throughout its lifecycle, from raw material to final assembly. This continuous chain of custody delivers unmatched transparency, allowing manufacturers to pinpoint exactly which parts are affected during a defect or recall.

Successful implementation often includes:

- Standardizing data formats across suppliers

- Balancing data security and accessibility

- Managing high volumes of traceability data

- Integrating with legacy manufacturing platforms

The results? Streamlined compliance, lower recall costs (up to 40% reduction for early adopters), and better insight into every component’s origin and movement.

Anti-Counterfeiting and Authentication

The rise in counterfeit automotive components is not just a financial issue; it’s a critical safety concern. As a result, investment in anti-counterfeiting and authentication technology has surged by over 35% in the past five years.

The most effective systems combine physical and digital security layers, making it extremely difficult for counterfeiters to replicate or infiltrate supply chains. Blockchain-based systems, in particular, are proving to be a game-changer by ensuring that each component has a secure, tamper-proof record of its journey.

For OEMs, every dollar invested in authentication solutions yields an estimated $7 in counterfeit-related savings, according to industry research.

How ARVO Helps Achieve Supply Chain Transparency?

At ARVO, we specialize in integrated anti-counterfeiting solutions that help automotive OEMs protect their supply chains, brands, and customers. Our smart label technology goes beyond tracking, delivering powerful tools for authentication and traceability.

We offer:

- Copy-proof codes and Invisible Watermarking for secure, tamper-resistant product verification

- Vision AI and Tamper-Proof NFC Tags to detect counterfeits and unauthorized access

- Digital Product Passports, powered by blockchain, assign each component a unique, tamper-proof identity

- End-to-end traceability from raw material sourcing to final assembly and distribution

- Seamless system integration, tailored to meet the specific challenges of the automotive industry

What sets ARVO apart is our flexible technology architecture. Our system easily integrates with existing ERP and MES platforms, minimizing disruption and accelerating ROI. Whether you’re launching a pilot program or scaling across multiple production lines, ARVO provides tailored implementation strategies built around your specific challenges.

Our expert team collaborates closely with your operations, IT, and supply chain stakeholders to ensure a smooth rollout and long-term success.

Ready to Build a Transparent, Resilient Supply Chain?

Don’t let blind spots in your supply chain jeopardize your production quality or brand trust. Partner with ARVO and take control of your supply network with intelligent labeling solutions purpose-built for the automotive industry.

Contact us today to schedule a personalized consultation and discover how ARVO can help you enhance transparency, fight counterfeiting, and future-proof your manufacturing operations.

FAQ

1. What are smart labels, and how do they benefit automotive OEMs?

Smart labels are advanced identification tags that include technologies like copy-proof codes, invisible watermarking, and tamper-evident features. Automotive OEMs offer real-time tracking, enhance component authentication, and provide full visibility across the supply chain, helping reduce counterfeits, streamline recalls, and improve regulatory compliance.

2. How do ARVO’s solutions help prevent counterfeit automotive parts?

ARVO uses a combination of secure technologies, including copy-proof codes, invisible watermarking, Vision AI, and tamper-proof NFC tags, to make it nearly impossible for counterfeit parts to enter your supply chain. Each product is uniquely identified and traceable, ensuring authenticity at every stage.

3. What is a Digital Product Passport, and why is it important?

A Digital Product Passport is a blockchain-powered digital identity assigned to each component. It stores secure data about the product’s origin, movement, and ownership. This ensures tamper-proof traceability, enhances transparency and helps OEMs meet regulatory and sustainability requirements.

4. Can ARVO’s technology integrate with existing ERP and manufacturing systems?

Yes. ARVO’s platform is designed for seamless integration with existing ERP, MES, and supply chain systems. This allows for minimal disruption during implementation and ensures real-time data sharing across your operations.

5. Which industries can benefit from ARVO’s smart labeling solutions?

While ARVO is highly effective in the automotive industry, our anti-counterfeiting and traceability solutions are also widely used in pharmaceuticals, consumer electronics, fashion, and other high-risk sectors that require secure, transparent supply chains.