Consider a multi-million dollar gas turbine, a batch of life-saving biopharmaceuticals, or a tailor-made aerospace part. The production was perfect, all specifications were achieved, and all quality tests were done. But when it went out of your factory gates, it went into a black box. You have little more than a prayer and a standard tracking number; you cannot tell where it is, its state, or even when it arrived, in the next 15 days.

It is not a hypothetical fear. High-value manufacturers are faced with it as a reality. The path taken by the factory to the customer is laden with financial, reputation, and operational risks since we are not aware of what is happening to the product. It’s not enough to know that a package is in transit. We must be aware of its status, safety, and time of arrival.

This paper describes the reasons why end-to-end visibility is no longer a luxury, the technology that enables it, and a basic guide to transform your supply chain from a black box into a transparent and data-rich experience.

What is Full Supply Chain Visibility?

Visibility is a word that is frequently used in logistics discussions, but in high-value manufacturing, it is much more than tracking a shipment or checking an ETA.

Full supply chain visibility is concerned with knowing all the moments of a product’s life cycle, where it is, how it is performing, and what is happening to it. It transforms complicated world supply chains into real-time, data-driven narratives you can actually track.

There are three main pillars of true visibility:

Location Awareness (Where is it?)

GPS tracking, geofencing, and route deviation notifications will show you precisely the location of your assets and whether they are heading in the right direction.

Condition Monitoring (How is it?)

IoT sensors constantly measure temperature, humidity, shock, tilt, and light exposure- making sure that all products are in safe conditions during the delivery.

Status & Custody (What is happening to it?)

Computer records confirm the name of the person who received the product, the time it was cleared by customs, and that the container was opened. All the events in the journey are recorded, time-stamped, and authenticated.

Analogy: Imagine it is the difference between receiving a postcard from a traveler and having a live video call with them throughout their trip.

Why Visibility is CRITICAL for High-Value Manufacturing

- Better security and theft deterrence: Valuable items are the best targets of theft. Quick security measures can be taken by real-time notifications of route alterations or container openings, and you can avoid loss.

- Strict quality control: In products such as medicine and chips, even a slight increase in temperature may spoil the product. Sensors enable producers to ensure that products remain in ideal conditions throughout the production process.

- Improved operations: Goodbye to shipment losses. Visibility prevents delays in production and waiting time by customers through early detection of problems.

- Customer service: Customers who purchase high-quality and expensive products want to be assured of quality delivery. Detailed tracking in real-time creates trust and retains customers.

Strong chain of custody and compliance: Regulated companies should be transparent by law. Complete visibility generates an unchangeable digital trail that satisfies the regulations and demonstrates that all the steps are right.

The Full Visibility: More Than a Dot on a Map

High-value goods cannot be tracked by a carrier using standard tracking. Full visibility is not just a simple location update, but a living digital representation of your physical supply chain. It provides you with practical information, not historical information.

The modern visibility is based on three critical pillars:

1. Location Intelligence: This is not just simple GPS points, but real-time tracking with high accuracy, which is sometimes in a few meters. Geofencing allows you to create virtual fences around important locations such as a factory, a warehouse, a customer location, and receive automatic notifications of arrivals, departures, or unforeseen routes.

2. Condition Monitoring: IoT sensors cannot be ignored in this case. These miniature gadgets are placed on shipments or packages and continuously scan the most important environmental and handling factors:

– Temperature and Humidity: Requirement of medicines, chemicals, and sensitive electronics to prevent damage.

– Shock and Vibration: This is significant in sensitive equipment, scientific equipment, and precision components to detect rough handling.

– Tilt and Orientation: Notifies you in case of the tipping or inversion of goods that are not supposed to be tipped.

– Light Exposure: Displays whether a container has been opened prematurely or not, enhancing security.

3. Data Integration: When all this different data is combined, the real power is achieved. One platform, or control tower, combines sensor information with your ERP, WMS, and TMS information. This provides a single trusted source of reality and a complete real-time perspective of the entire supply chain.

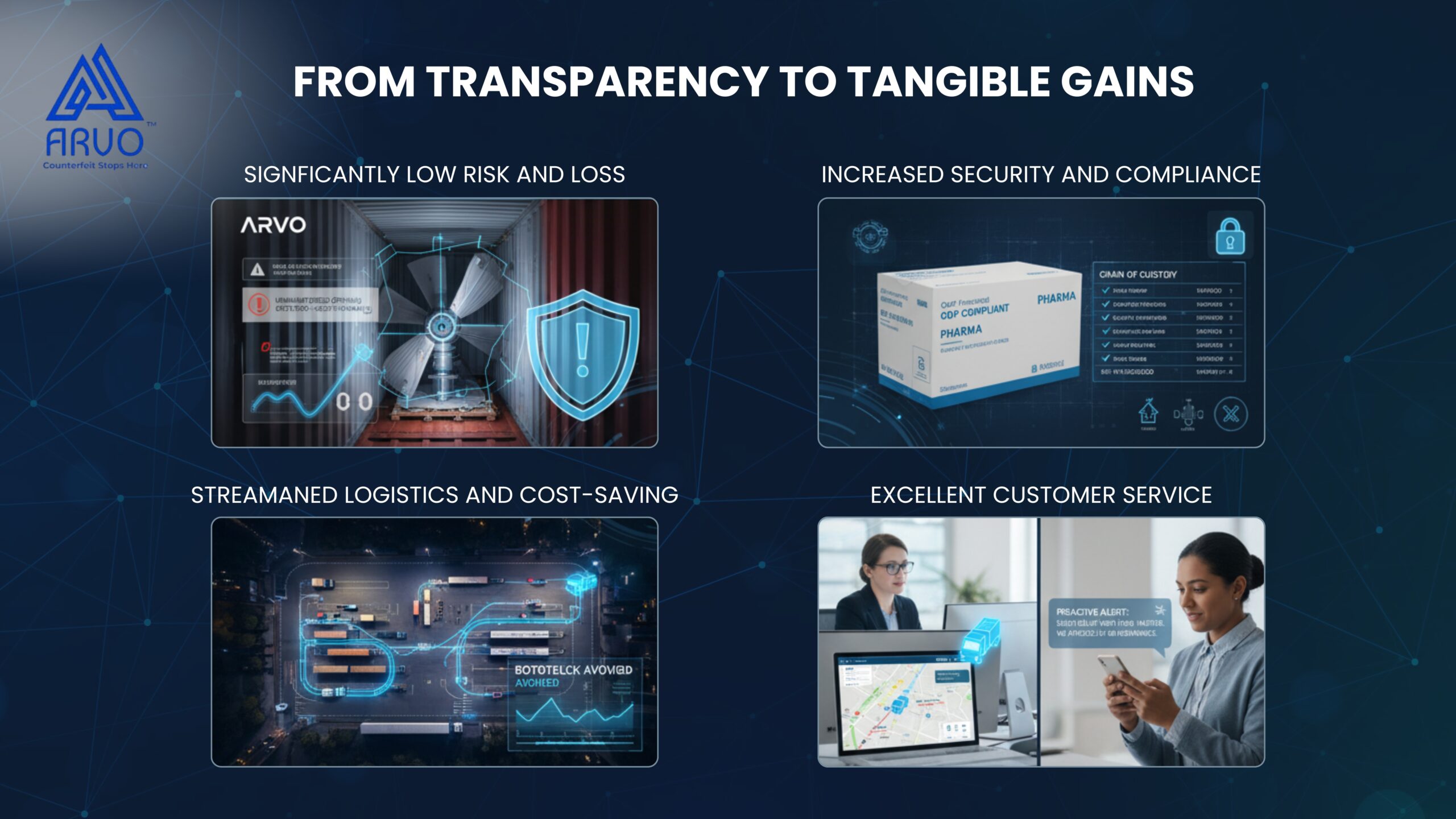

The payback of Seeing Everything: Tangible Benefits of a Transparent Supply Chain.

It is not only the reduction of risk that is involved in investing in end-to-end visibility in high-value manufacturing; it opens actual operational and financial benefits that will keep you competitive.

Significantly low Risk and Loss

You can monitor assets in real time and intervene before they are stolen or damaged. The route change or unauthorized openings alert notices allow you to react swiftly and get back on track.

Increased Security and Compliance

A fixed history of place and state forms a strong chain of custody. This is necessary in the regulations, such as the GDP of pharmaceuticals, and provides uncontrovertible evidence in a case or insurance claim.

Streamlined Logistics and Cost-Saving

Live data reveals inefficiencies. Eliminate bottlenecks, reduce time wasted at transfer points, and enhance routes. Even predictive analysis can assist in avoiding costly delays before they happen.

Excellent Customer Service

Stop correcting the situation when it occurs and inform customers about the possible delays before they realize. Give accurate, dynamic ETAs that generate trust and satisfaction.

Data‑Driven Decision Making

Each delivery is a piece of data. You may learn about the past trends in transit times, temperature spikes, or handling incidents. Apply these lessons to better package, select more favorable carriers, negotiate more favorable freight terms, and continue to optimize your supply-chain operations.

Conclusion: Stop Shipping Blind

Full supply chain visibility is no longer a luxury to high-value manufacturers, but a strategic necessity. It safeguards revenue, reduces risk, and fosters brand trust. Each delivery is a fact-based narrative of trust. In cases where the cost of a lost or damaged shipment may exceed the cost of the implementation of a complete visibility solution, the real question is: Could you afford not to do it?

FAQs

1. What technologies are essential for achieving full supply chain visibility?

The key technologies for complete supply chain visibility are RFID tags, GPS trackers, Internet of Things sensors, and data integration tools. In addition to integrating with ERP, WMS, and TMS to guarantee that all the data is viewable in one place, they offer real-time information about the location, status, and ownership of objects.

2. How does supply chain visibility improve security for high-value products?

Manufacturers can quickly determine whether a product has strayed from its intended course, been accessed without permission, or the environment has changed by using geofencing, real-time warnings, and condition checks. This enables them to take this action beforehand to avoid damage, theft, or tampering.

3. Is full visibility only relevant for industries like aerospace or pharmaceuticals?

Aerospace or pharma are not the only ones that can be fully visible. Although those industries have high risk, any business that manufactures valuable, sensitive, or regulated goods, such as luxury electronics or medical equipment, can employ real-time visibility to remain in compliance, operate more efficiently, and provide assurance to its customers.

4. What are the first steps to implement end-to-end visibility in my supply chain?

The most important assets and delivery paths should be listed first. Install IoT sensors on them to monitor their position and well-being. Then input the data into a central visibility platform or control tower. Subsequently, apply analytics to enhance the process, reduce risks, and anticipate issues.