Poll insight: Studies suggest that 20 to 30 percent of aftermarket margins disappear through grey market diversion. Do you track it, or do you absorb it as part of the business?

The Margin Leak Nobody Tracks

Counterfeits have always taken the spotlight. They are visible, they are easy to condemn, and they make headlines when enforcement succeeds.

The quieter threat is diversion. These are genuine OEM parts that find their way into markets or channels where they were never intended to be sold.

The fallout is serious. Pricing structures collapse, dealers lose faith, and the brand’s reputation starts to slip. When as much as a third of margins are lost this way, it is not just a financial hit. It is a long-term erosion of competitiveness.

Why Diversion Hurts More Than Counterfeits

Counterfeits can be chased down. They are the enemy outside the gates. Diversion is more insidious because it happens inside the system.

- Channel erosion. Dealers who play by the rules suddenly find themselves competing with unauthorized sellers who offer genuine parts at lower prices.

- Pricing instability. Once diverted stock appears in the open market, the official price list loses weight. Dealers discount heavily just to keep business.

- Warranty and compliance issues. Parts meant for one region may not meet the safety or emission standards of another. When failures occur, customers hold the OEM responsible.

- Damage to brand perception. Buyers do not blame the middlemen. They look at the manufacturer and assume the supply chain is out of control.

Counterfeit seizures get attention. Diversion erodes margins quietly until the financial damage becomes impossible to ignore.

The Tech Gap

Most automotive supply chains still rely on serialization at the batch level and basic barcodes for authentication. These systems are decades old and relatively easy to copy. Without visibility at the level of each unit, parts can move into unauthorized markets with little resistance.

This lack of precision is what allows grey market operators to thrive.

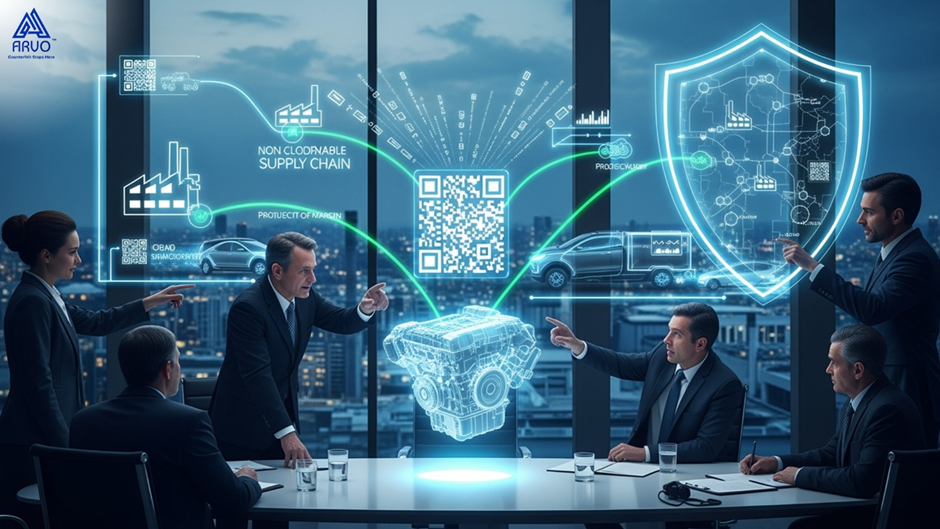

A New Layer of Defense

Technology has moved on. Non-cloneable QR codes, built on cryptographic principles and physical unclonable functions (PUFs), create a level of security that earlier systems could not deliver.

Each code is unique to the unit it marks. It cannot be copied or reused, and every scan feeds back into the OEM’s central system. In effect, every part carries its own passport.

What This Means for Margins

When applied across the supply chain, non-cloneable QR codes make diversion far more difficult.

- At the dealer level, every transaction can be traced. If a product surfaces in the wrong geography, the source of the leak becomes clear.

- For OEMs, alerts arrive in real time rather than months later during an audit.

- Dealers regain confidence that they are not being undercut by backdoor sales.

- Even recovering a fraction of the lost 20 to 30 percent can add millions to the bottom line for large manufacturers.

Case Study: Asia’s Two-Wheeler Market

In 2023, several two-wheeler brands in Asia began using non-cloneable QR codes across their aftermarket channels. Within the first year, grey market diversion dropped by nearly 40 percent. The shift also improved dealer relationships. Confidence in the official channel was restored, and sales performance reflected that. Customers scanning the codes gained access to loyalty programs and service offers, which created new revenue streams on top of the protection benefits.

More Than Compliance

Global regulation is tightening. Europe and North America already require stricter authentication for safety-critical components, and other regions are likely to follow.

For OEMs, adopting non-cloneable QR codes now is not only about staying compliant. The advantages are wider:

- Lower warranty costs as diverted parts disappear from circulation.

- Clear visibility of product movement across global markets.

- Data that informs smarter decisions on supply chain planning and dealer support.

In an industry where two or three points of margin can decide competitiveness, losing up to 30 points to diversion is unsustainable.

The Way Forward

Revenue protection is not optional, it is a deliberate strategy. OEMs that move early with non-cloneable QR codes will set the benchmark for trust, compliance, and long-term competitiveness.

ARVO partners with manufacturers to close the diversion gap by deploying secure, non-cloneable QR technology that gives every part a unique identity and every margin full visibility. The tools are proven, the results are measurable, and the opportunity is immediate.

Do not allow margins to keep slipping away. Secure them with ARVO.

Frequently Asked Questions

1. What exactly is grey market diversion in the automotive industry?

Grey market diversion happens when genuine OEM parts are sold outside their intended channel or region. Unlike counterfeits, the parts are real, but they end up in unauthorized markets, often at lower prices, which disrupts official pricing and damages dealer relationships.

2. How is diversion different from counterfeit parts?

Counterfeit parts are fake and usually easy to identify as an external threat. Diversion is more complex. The parts are genuine, but because they are sold in the wrong market, they create pricing instability, regulatory risks, and erode dealer trust.

3. Why can’t traditional barcodes and serialization stop diversion?

Barcodes and batch-level serialization are easy to copy and lack unit-level visibility. As a result, parts that leave their intended path can easily slip into other regions or show up with unauthorized sellers, often without anyone noticing until the damage is done.

4. How do non-cloneable QR codes work?

They work by blending cryptography with a technology known as physical unclonable functions (PUFs). In practice, this creates a code that is unique to each part and cannot be duplicated. When someone scans it, the information connects back to the OEM’s system, revealing where the part was sold and how it has moved through the network. Instead of tracking by batch, every single unit can now be followed on its own path.

5. What business benefits do OEMs gain from adopting this technology?

The most immediate gain is revenue protection. Even recovering part of the 20–30 percent lost to diversion adds millions to the bottom line. On top of that, dealers regain confidence, warranty costs go down, compliance becomes easier, and customer engagement improves through scan-based loyalty and service programs.